In welding operations where scorching flames and flying metal fragments create a hazardous environment, every second carries hidden dangers. Molten metal droplets can reach temperatures of thousands of degrees Celsius during the process. If these droplets land on regular shoe surfaces, they instantly burn through the material and cause severe burns to the feet. Sharp metal edges and heavy tools falling from heights may also inflict irreversible injuries to the feet.

Meanwhile, the complex working conditions in the welding workshop, such as oil stains, humidity, and conductive areas, greatly increase the risk of slipping and electric shock.Therefore, high-quality welding boots that can withstand these dangers are the first line of defense for welders’ safety and essential equipment for improving work efficiency.The best welder boots not only comprehensively address various threats but also provide comfortable wear, ensuring every operation is performed with greater confidence.

On the industrial stage where safety and protection dance in harmony, MK Safety redefines safety standards through over a decade of professional expertise. They understand that true protective gear must feel as natural as an extension of the body. Each pair of welding boots is a masterpiece of precision ergonomics. MK Safety firmly believes the best protection makes workers forget it’s there.

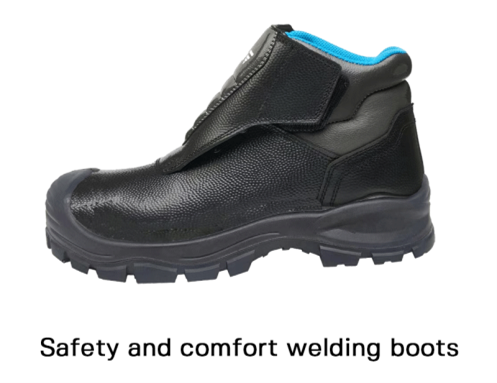

These men’s welding boots feature a high-top black design with dual-layer cowhide upper for breathability and durability. The PU sole delivers slip-resistant traction and shock absorption, while the steel toe cap and plate provide exceptional impact resistance and puncture protection. The anti-static design meets industrial safety standards, ensuring comprehensive foot protection. Custom OEM modifications are available to meet personalized needs. The high-top construction safeguards ankles from welding sparks and heat hazards, combining multiple protective features like impact resistance, slip resistance, and shock absorption for reliable welding protection.

As a seasoned manufacturer in the field of welding protection, MK Safety has redefined industry standards with innovative technologies. Its welding boots not only feature core protective components such as heat-resistant soles and puncture-resistant linings, but also offer all-weather comfort through a lightweight design. This makes them the benchmark for industrial protective equipment.

In-depth analysis of the hardcore features of welding boots

- High temperature resistance and anti-scalding: The best welding boots are usually made of special fire-retardant materials, which can withstand the direct attack of high temperature metal slag and sparks, effectively prevent scalding and protect the skin of the foot from high temperature burns.

- Impact Protection: Welding sites often involve heavy machinery and tools, making accidental falls a common occurrence. These premium welding boots feature built-in high-strength steel toe caps or composite protective covers that withstand intense impacts. When heavy objects strike, they create a robust protective barrier around the feet, effectively preventing serious injuries like toe fractures.

- Anti-slip and Wear-resistant: Facing the complex ground conditions in welding workshops, the soles of high-quality welder boots are designed with special anti-slip patterns and wear-resistant rubber materials to enhance friction with the ground and prevent slipping. Meanwhile, excellent wear resistance ensures the boots maintain good performance over long-term use, extending their service life.

- Breathable and comfortable: After a long time of welding, the feet are easy to sweat and stuffy. High-quality welder’s boots pay attention to protection at the same time, but also take into account the breathability. They use breathable fabric to discharge the moisture on the feet in time, keep them dry, reduce fatigue and improve working comfort.

How to accurately choose professional welding protective boots?

- Identify safety standards: Choose welding boots that have passed the authoritative safety certification, such as MK Safety, which meet the relevant safety indicators of national standards. These certification marks are an important guarantee of product quality and safety, ensuring that the boots have the necessary protective functions.

- Supplier Qualification: Selecting reputable a safety shoes supplier is crucial. A reliable supplier not only provides high-quality welding boots but also maintains a comprehensive after-sales service system that promptly resolves any issues encountered during use, ensuring you have no worries.

- Tailor to your needs: Choose welding boots that match your specific working environment and requirements. Different welding scenarios require different boot features. For instance, insulated boots are indispensable in electrical environments, while waterproof design is crucial in damp conditions.

Next, we will introduce the two most popular professional protective boots for welders in the current market. These products provide customized solutions for different working scenarios through innovative design and strict certification.

These professional welding boots deliver unmatched protection, lasting durability, and comfort through their specialized design. The upper features imported black S2 calfskin with bold polka dots, offering robust wear resistance to withstand welding sparks and high temperatures. The steel toe cap meets 200J impact safety standards, combined with a fiberglass toe cap for dual protection. The reinforced midsole blends steel and Lycra® fabric, providing 1100 Newtons of puncture resistance to safeguard your feet. Choose between warm fleece or breathable black air-drying mesh for different environments, while the EVA foam insoles ensure maximum comfort. Cold-adhesive technology enhances structural stability and longevity, ensuring comprehensive protection throughout welding operations from material selection to craftsmanship.

These welding boots feature a rugged horsehide upper and rubber soles, reinforced with cold bonding technology for structural stability. The steel toe meets 200J impact resistance standards, paired with Kevlar midsole that deliver exceptional puncture protection. Combining comfort and practicality, the breathable black air-drying mesh lining keeps feet dry, while the anti-static molded sole reduces fatigue. Their durability withstands welding-related impacts and punctures, while the ergonomic design enhances foot safety and comfort during work. As reliable equipment for industrial operations, especially in welding scenarios, they ensure enhanced foot protection and user experience.

Why choose MK safety shoes as your welding boots?

MK Safety Welding Protective Boots harness innovative technology to meet diverse operational needs across all scenarios. The comprehensive product line offers tailored solutions for various applications: from basic heat-resistant models to smart protection variants, and from routine operations to extreme environments. These boots provide precision-matched professional protection for welders, having delivered reliable safeguards to tens of thousands of workers worldwide. By seamlessly integrating industrial-grade safety with specialized protection, they deliver exceptional protection that adapts to every welding environment.