Shrinkage

Shrinkage is the phenomena in which the length or width of textiles varies following washing, drying, or other treatments in a certain state. Fabric shrinkage is the percentage of fabric that shrinks after washing or soaking in water.

The fiber content, weaving, finishing, and environmental factors all affect how much the cloth shrinks. Shrinkage can occur in both lengthwise (warp) and widthwise (weft) directions. Both natural and synthetic textiles can shrink, which can have a big impact on how a garment fits and looks. Manufacturers evaluate the shrinkage potential of their products using a variety of fabric shrinkage test methods to guarantee that materials retain their form and size.

There are numerous types of fabric shrinkage test methods, and each has its own standards and protocols including the dimensional stability test, tumble dryer test, steam press test, and washing machine test.

Conventional method for fabric shrinkage rate testing

The dimensional stability test, which gauges a fabric’s change in dimensions following a certain washing or drying procedure, is one of the most often used techniques.

Testing procedure

- Prepare the specimen by cutting it 25cm×25cm. 5 specimen in warp and 5 in weft direction is needed.

- The specimen are marked by using a texpen following a given template

Fig: Sample preparation and marking in conventional method

- Then the dimension of the specimen in warp and weft direction is measured by measuring tape and data is recorded in the data sheet. These are before wash data

- Then the specimen are subjected to washing according to care label following a specific test method

- Then the specimen are dried, conditioned in standard atmospheric condition and the measurement of the marked area is taken again. These are after wash data

- Then shrinkage% is measured from the below formula:

Shrinkage Percentage = [(Initial Dimension – Final Dimension) / Initial Dimension] x 100

For example, if the initial length of the fabric sample was 100 cm and the final length after testing was 90 cm, the calculation would be:

Shrinkage Percentage = [(100 – 90) / 100] x 100 = 10%

The resultant figure indicates the extent of contraction experienced by the fabric sample during the testing procedure.

This method takes a long time and chance of error during measurement is more. Thus to minimize the processing time from 6 minutes to 5 second Smart fabric shrinkage rate tester is introduced.

Smart fabric shrinkage rate tester

This instrument has an automated system that measures fabric shrinkage and calculates the test findings, eliminating the possibility of human errors and ensuring a more precise and dependable test.

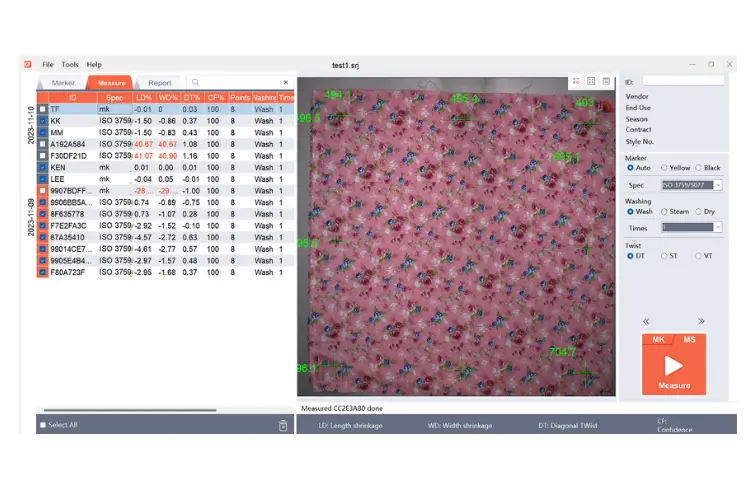

Using a camera mounted on top, it automatically measures the distances between the indicated dots on a fabric sample and uses a patented vision inspection algorithm to compute the test findings.

Fig: Smart fabric shrinkage tester (ChiuVenton-SmartShrink)

Testing procedure

- Prior to washing, label the dots and utilize this device to read the fabric sample’s code and determine its information;

- The Smart Fabric Shrinkage Rate Tester measures the lengths between the dots on the warp and weft directions of the fabric automatically when the sample is placed flat on its platform following washing;

- Using computer software, the Fabric Shrinkage Rate Tester will automatically determine the shrinkage rate in real-time and store the test findings to create a report.

Fig: Smart shrinkage measuring technique

Which approach is the future?

- When using a traditional method that involves manual labor, the error rate increases with workload, intelligent and automated measuring is quicker, more precise, and less prone to error!

- The test results from reputable worldwide third-party laboratories are equivalent to the test data obtained in a smart tester.

- In smart tester regardless of whether the samples are from the same set or various computers of the same type, the results remain consistent after doing many tests.

- The test is more transparent and reliable in smart tester since it automatically records the test data and sample photographs and allows real-time sharing and sending of the test findings

- The test findings from smart tester can be uploaded immediately to the ERP or LIMS system. It enables convenient and effective management of shrinkage test results.

The textile industry’s approach to fabric quality monitoring is being revolutionized by the development of shrinkage rate testers. This modern instrument is vital for contemporary producers because of their unmatched precision, quick testing, intuitive interfaces, intelligent connection, eco-friendly designs, and adaptable uses. It’s imperative to adopt these advancements to remain competitive and satisfy today’s demanding customers.

References

- https://fyitester.com/fabric-shrinkage-test/

- https://qtrllab.org/understanding-fabric-shrinkage-and-exploring-the-smart-shrink-rate-tester/

- https://chiuvention.com/product/fabric-shrinkage-test-machine#:~:text=The%20Shrinkage%20Rate%20Tester%20can,quality%20of%20the%20fabric%20more.

- https://www.linkedin.com/pulse/how-many-kinds-fabric-shrinkage-test-method-nana-textile-tester–srs8c?utm_source=share&utm_medium=member_android&utm_campaign=share_via

Author Information

Mahzabin Mosharrof

M.Sc in Textile Engineering, DUET (ongoing)

Former Lab Technologist of Hohenstein BD

Currently working as Instructor of NIET, Dhaka.

Email: [email protected]